Mechanical Binding > Coil Binding > Oval Hole

Plastic coil binding is the newest form of mechanical binding and is the fastest growing. It consists of a plastic element that typically has 4 holes to every inch. Plastic coil is very resilient and ideal for mailing, or other long term applications. The pages can be turned 360˚ and the book can lie flat, this makes coil binding an ideal choice for manuals, business reports, and workbooks.

![]()

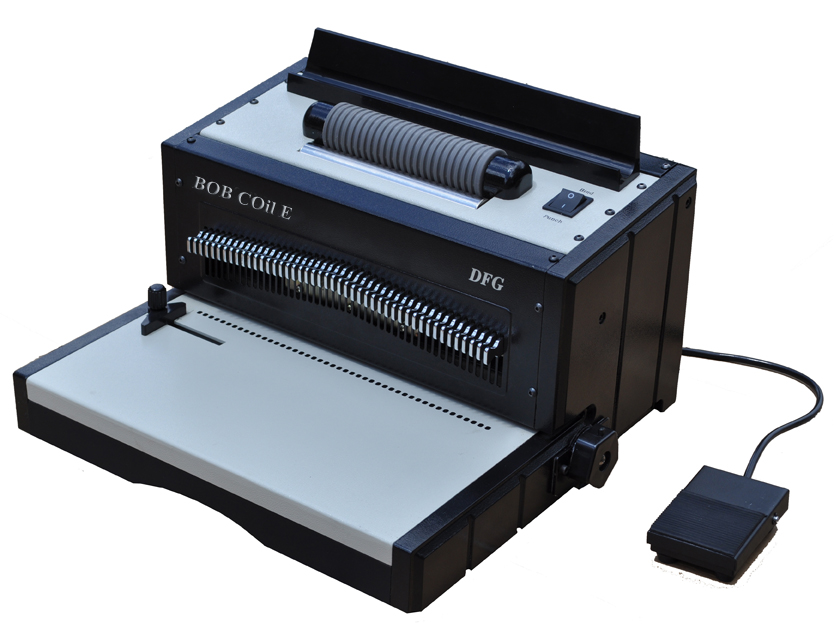

DFG’S BOB Coil E is the first and only extra heavy duty electrical coil punch and binding machine in its class. It can punch world record 30 sheets (20#, double D oval hole) or 3 mm hardboard in one punch. This is due to DFG’s Hi-Torq™ punch motor and innovative super strength machine design. With DFG’s SERVOGROVE™ Roller Binding System, it binds small or larger books (up to 22 mm) effortlessly. Lager size coil is not difficult with some practice. BOB Coil E can punch and bind any length and thickness of book.

All Electric Operation: Extra Heavy Duty Electrical Coil Punching and Coil Binding with the simple press of a foot pedal.

Punches a double “D” oval hole (4x5mm hole) which increases the binding speed and makes it easier to bind thicker books. DFG double “D” oval hole is a True .250” pitch. This is important because plastic coil construction is .250” pitch and this makes it faster and easier to drive the coils into the book. With fully dis-engagable punch pin design, 0.250” pitch is far superior to 0.248” pitch. It makes books stronger and tolerant of paper size fluctuation, which is very common in today’s digital printing (letter size sheets 8.5”x11” cut from 12” x 18” sheets). DFG only uses 0.248” pitch for low cost coil machines that don’t have dis-engagable punch pin design.

For any length and thickness book: Punch any length of paper with our open throat die and alignment pin. DFG’s design makes it possible to punch paper of any length with no restrictions. Whatever your paper length is, you can punch it on the BOB Coil E. After the first punch, put one hole through the alignment pin to keep your subsequent punches aligned correctly and punch again. You will have perfect alignment for the full length of paper.

High Volume Punch Capacity: With our specially designed Hi-Torq™ punch motor, DFG torture tested it for 200,000 trouble free punch cycles. The BOB Coil E can punch 30 sheets of 20 lb paper or 3mm (1/8” thick) hardboard covers with the gentle push on the foot pedal. No other table top punch and bind machine in its class can accomplish this task.

Super Strength Punch Mechanism: Cast-hardened & heat-treated precision steel punch pins provide superior strength & hardness. You add DFG’s lubrication system, and that drastically reduces friction and punch pin wear. This equates to longer machine life and a sharp clean perforation every time for the end user. High-Speed, commercial punches that cost over $30,000 lubricate their punch pins. DFG utilizes this technology in our commitment to taking the extra step to deliver the best machine possible to the market place.

Heavy duty Chassis: Countless years of experience has led DFG to produce a machine with the most sophisticated design, testing methods, and manufacturing techniques to develop the most rigid heavy duty chassis in its class at 29% less overall machine weight.

New Patent Pending SERVOGROVE ™ Roller Binding System: This new roller system binds small or larger books (up to 22 mm) effortlessly. Absolutely no costly separate coil inserter needed. Manually binds any size book. The SERVOGROVE ™ Roller Binding System dramatically increase binding speed, when compared against smooth roller systems by 50%. Once the coil is started, simply lay the book against the grooved roller. The coil is easily inserted into the book, making this inserter one of the easiest-to-use. Top-mounted roller position will give the operator greater control, improve their efficiency, and have less operator fatigue, which improves production. A foot-pedal activates the roller and is compatible with plastic & metal coils.

Full Die Disengagement Pins: Utilizing the DFG’s World’s First full disengagement-pin design for coil binding machines (recently copied by other manufacturers), our punched paper is free from partial punches, on any size project. Our disengagement-pin design uses independent coil spring mechanisms on each pull pin that allows the pins to disengage with a crisp snapping action. Our punch pins are heat treated and precisely ground to ensure consistent, clean, punching.

J-Shaped Book Pre-former Guide: It is essential when binding thicker books (1/4” or thicker) to have the ability to form the book to the proper radius of the Coil. This is why DFG has developed the J-Shaped Book Pre-former Guide as opposed to utilizing U shaped pre-former. The J-shaped Book Pre-former Guide supports the book better than a U shape guide because it supports the back of the book better. This solves book buckling and will assist the operator to properly shape the book’s spine, for faster & easier coil insertion. The J-shaped pre-former concept is widely used in larger, automatic binding machines.

Side Margin Control: Allows you to evenly center your punch pattern on your sheet.

Punching Margin Control: Provides the correct punch depth for each coil size. This will maximize the book's tear resistance

: The BOB Coil E is made of DFG precision engineered die-casting base and side plates rather than low-cost, flexible sheet metal like some other machines in its class. DFG uses die casted metal for the base and sides of the housing unit to insure your machine is solid in all the important places which significantly improves machine life as compared to sheet metal base construction. Any base deflection can shorten the life of the machine

Exclusive built-in lubrication system to ensure longer punching tool life.

Built-in temperature regulating system successfully solves motor over heating issues at high volume environment, which makes machine safer and lasts longer.

Large Waste Drawer

Anti-Jam Function: For trouble-free punching.

Non-Skid Feet

Includes DFG’s Heavy Duty Oval Hole Coil Crimpers

BOB COil E Specifications:

Model: |

BOB Coil E |

Punching Capacity |

30 sheets (20#) per punch |

Punch Length |

Any Length thanks to the fully disengagement pins and open throat design |

Binding Capacity |

Electrical binding up to 7/8”. Manual binding for any size |

Weight |

65 Lbs |

Dimensions |

21” x 19” x 14” |

Disengagement Pins |

Full set |

Power Supplier |

110/120 V AC, 60 HZ |

Warranty |

One year limited |

New Videos!

Punches a double “D” oval hole (4x5mm hole) which increases the binding speed and makes it easier to bind thicker books. DFG double “D” oval hole is a True .250” pitch. This is important because plastic coil construction is .250” pitch and this makes it faster and easier to drive the coils into the book.With fully dis-engagable punch pin design, 0.250” pitch is far superior to 0.248” pitch. It makes books stronger and tolerant of paper size fluctuation, which is very common in today’s digital printing (letter size sheets 8.5”x11” cut from 12” x 18” sheets). DFG only uses 0.248” pitch for low cost coil machines that don’t have dis-engagable punch pin design.

Punches a double “D” oval hole (4x5mm hole) which increases the binding speed and makes it easier to bind thicker books. DFG double “D” oval hole is a True .250” pitch. This is important because plastic coil construction is .250” pitch and this makes it faster and easier to drive the coils into the book.With fully dis-engagable punch pin design, 0.250” pitch is far superior to 0.248” pitch. It makes books stronger and tolerant of paper size fluctuation, which is very common in today’s digital printing (letter size sheets 8.5”x11” cut from 12” x 18” sheets). DFG only uses 0.248” pitch for low cost coil machines that don’t have dis-engagable punch pin design.

All Electric Operation: Heavy Duty Electrical Coil Punching and Coil Binding with the simple press of a foot pedal.

Extended Single Punching Length: Punch any length of paper with our open throat die and alignment pin. DFG’s design makes it possible to punch paper of any length with no restrictions. Whatever your paper length is, you can punch it on the Coil Ultimate E. After the first punch, put one hole through the alignment pin to keep your subsequent punches aligned correctly and punch again. You will have perfect alignment for the full length of paper.

High Volume Punch Capacity: With our specially designed Hi-Torq punch motor, DFG torture tested it for 200,000 trouble free punch cycles. The Coil Ultimate E can punch 30 sheets of 20 lb paper or 3mm (1/8” thick) hardboard covers with the gentle push on the foot pedal. No other table top punch and bind machine in its class can accomplish this task.

Super Strength Punch Mechanism: Cast-hardened & heat-treated precision steel punch pins provide superior strength & hardness. You add DFG’s lubrication system, and that drastically reduces friction and punch pin wear. This equates to longer machine life and a sharp clean perforation every time for the end user. High-Speed, commercial punches that cost over $30,000 lubricate their punch pins. DFG utilizes this technology in our commitment to taking the extra step to deliver the best machine possible to the market place.

Heavy duty Chassis: Countless years of experience has led DFG to produce a machine with the most sophisticated design, testing methods, and manufacturing techniques to develop the most rigid heavy duty chassis in its class at 29% less overall machine weight.

New Patent Pending SERVOGROVE ™ Roller Binding System: This new roller system binds small or larger books (up to 22 mm) effortlessly. Absolutely no costly separate coil inserter needed. Manually binds any size book. The SERVOGROVE ™ Roller Binding System dramaticaly increase binding speed, when compared against smooth roller systems by 50%. Once the coil is started, simply lay the book against the grooved roller. The coil is easily inserted into the book, making this inserter one of the easiest-to-use. Top-mounted roller position will give the operator greater control, improve their efficiency, and have less operator fatigue, which improves production. A foot-pedal activates the roller and is compatible with plastic & metal coils.

Full Die Disengagement Pins: Utilizing the DFG’s World’s First full disengagement-pin design for coil binding machines (recently copied by other manufacturers), our punched paper is free from partial punches, on any size project. Our disengagement-pin design uses independent coil spring mechanisms on each pull pin that allows the pins to disengage with a crisp snapping action. Our punch pins are heat treated and precisely ground to ensure consistent, clean, punching.

J-Shaped Book Pre-former Guide: It is essential when binding thicker books (1/4” or thicker) to have the ability to form the book to the proper radius of the Coil. This is why DFG has developed the J-Shaped Book Pre-former Guide as opposed to utilizing U shaped pre-former. The J-shaped Book Pre-former Guide supports the book better than a U shape guide because it supports the back of the book better. This solves book buckling and will assist the operator to properly shape the book’s spine, for faster & easier coil insertion. The J-shaped pre-former concept is widely used in larger, automatic binding machines.

Side Margin Control: Allows you to evenly center your punch pattern on your sheet.

Punching Margin Control: Provides the correct punch depth for each coil size. This will maximize the book's tear resistance

Rugged Die Cast Metal Construction: The Coil Ultimate E is made of DFG precision engineered die-casting base and side plates rather than low-cost, flexible sheet metal like some other machines in its class. DFG uses die casted metal for the base and sides of the housing unit to insure your machine is solid in all the important places which significantly improves machine life as compared to sheet metal base construction. Any base deflection can shorten the life of the machine

Exclusive built-in lubrication system to ensure longer punching tool life.

Built-in temperature regulating system successfully solves motor over heating issues at high volume environment, which makes machine safer and lasts longer.

Large Waste Drawer

Anti-Jam Function: For trouble-free punching.

Non-Skid Feet

Includes DFG’s Oval Hole Coil Crimpers

Coil Ultimate E Specifications:

Model: |

Coil Ultimate E |

Punching Capacity |

30 sheets one punch (20#) |

Binding Capacity |

Electrical binding up to 7/8”. Manual binding for any size |

Disengagement Pins |

Full |

Punch Length |

Any Length thanks to the fully disengagement pins and open throat design |

Hole Pattern |

True 4:1 pitch. 5 mm x 4 mm Double “D” hole |

Power Supplier |

110 V AC, 60 HZ |

Warranty |

One year limited |

Punches a double “D” oval hole (4x5mm hole) which increases the binding speed and makes it easier to bind thicker books. DFG double “D” oval hole is a True .250” pitch. This is important because plastic coil construction is .250” pitch and this makes it faster and easier to drive the coils into the book.With fully dis-engagable punch pin design, 0.250” pitch is far superior to 0.248” pitch. It makes books stronger and tolerant of paper size fluctuation, which is very common in today’s digital printing (letter size sheets 8.5”x11” cut from 12” x 18” sheets). DFG only uses 0.248” pitch for low cost coil machines that don’t have dis-engagable punch pin design.

Punches a double “D” oval hole (4x5mm hole) which increases the binding speed and makes it easier to bind thicker books. DFG double “D” oval hole is a True .250” pitch. This is important because plastic coil construction is .250” pitch and this makes it faster and easier to drive the coils into the book.With fully dis-engagable punch pin design, 0.250” pitch is far superior to 0.248” pitch. It makes books stronger and tolerant of paper size fluctuation, which is very common in today’s digital printing (letter size sheets 8.5”x11” cut from 12” x 18” sheets). DFG only uses 0.248” pitch for low cost coil machines that don’t have dis-engagable punch pin design.

All Electric Operation: Heavy Duty Electrical Coil Punching and Coil Binding with the simple press of a foot pedal.

Extended Single Punching Length: Punch any length of paper with our open throat die and alignment pin. DFG’s design makes it possible to punch paper of any length with no restrictions. Whatever your paper length is, you can punch it on the ETitanCoil Eagle. After the first punch, put one hole through the alignment pin to keep your subsequent punches aligned correctly and punch again. You will have perfect alignment for the full length of paper.

High Volume Punch Capacity: With our specially designed Hi-Torq punch motor, DFG torture tested it for 200,000 trouble free punch cycles. The ETitanCoil Eagle can punch 30 sheets of 20 lb paper or 3mm (1/8” thick) hardboard covers with the gentle push on the foot pedal. No other table top punch and bind machine in its class can accomplish this task.

Super Strength Punch Mechanism: Cast-hardened & heat-treated precision steel punch pins provide superior strength & hardness. You add DFG’s lubrication system, and that drastically reduces friction and punch pin wear. This equates to longer machine life and a sharp clean perforation every time for the end user. High-Speed, commercial punches that cost over $30,000 lubricate their punch pins. DFG utilizes this technology in our commitment to taking the extra step to deliver the best machine possible to the market place.

Heavy duty Chassis: Countless years of experience has led DFG to produce a machine with the most sophisticated design, testing methods, and manufacturing techniques to develop the most rigid heavy duty chassis in its class at 29% less overall machine weight.

New Patent Pending SERVOGROVE ™ Roller Binding System: This new roller system binds small or larger books (up to 22 mm) effortlessly. Absolutely no costly separate coil inserter needed. Manually binds any size book. The SERVOGROVE ™ Roller Binding System dramatically increase binding speed, when compared against smooth roller systems by 50%. Once the coil is started, simply lay the book against the grooved roller. The coil is easily inserted into the book, making this inserter one of the easiest-to-use. Top-mounted roller position will give the operator greater control, improve their efficiency, and have less operator fatigue, which improves production. A foot-pedal activates the roller and is compatible with plastic & metal coils.

Full Die Disengagement Pins: Utilizing the DFG’s World’s First full disengagement-pin design for coil binding machines (recently copied by other manufacturers), our punched paper is free from partial punches, on any size project. Our disengagement-pin design uses independent coil spring mechanisms on each pull pin that allows the pins to disengage with a crisp snapping action. Our punch pins are heat treated and precisely ground to ensure consistent, clean, punching.

J-Shaped Book Pre-former Guide: It is essential when binding thicker books (1/4” or thicker) to have the ability to form the book to the proper radius of the Coil. This is why DFG has developed the J-Shaped Book Pre-former Guide as opposed to utilizing U shaped pre-former. The J-shaped Book Pre-former Guide supports the book better than a U shape guide because it supports the back of the book better. This solves book buckling and will assist the operator to properly shape the book’s spine, for faster & easier coil insertion. The J-shaped pre-former concept is widely used in larger, automatic binding machines.

Side Margin Control: Allows you to evenly center your punch pattern on your sheet.

Punching Margin Control: Provides the correct punch depth for each coil size. This will maximize the book's tear resistance

Rugged Die Cast Metal Construction: The ETitanCoil Eagle is made of DFG precision engineered die-casting base and side plates rather than low-cost, flexible sheet metal like some other machines in its class. DFG uses die casted metal for the base and sides of the housing unit to insure your machine is solid in all the important places which significantly improves machine life as compared to sheet metal base construction. Any base deflection can shorten the life of the machine

Exclusive built-in lubrication system to ensure longer punching tool life.

Large Waste Drawer

Anti-Jam Function: For trouble-free punching.

Non-Skid Feet

Includes DFG’s Oval Hole Coil Crimpers

ETitanCoil Eagle Specifications:

Model: |

ETitanCoil Eagle |

Punching Capacity |

1-26 sheets one punch (20#) |

Binding Capacity |

Electrical binding up to 7/8”. Manual binding for any size |

Disengagement Pins |

Full |

Punch Length |

Any Length thanks to the fully disengagement pins and open throat design |

Hole Pattern |

True 4:1 pitch. 5 mm x 4 mm Double “D” hole |

Power Supplier |

110 V AC, 60 HZ |

Warranty |

One year limited |

Low cost version of EtitanCoil Eagle for the people who want a heavy duty, electric punch and binding machine but have a limited budget.

For specs and videos, please see the ETitanCoil Eagle.

![]()

Punches a double “D” oval hole (4x5mm hole) which increases the binding speed and makes it easier to bind thicker books. DFG double “D” oval hole is a True .250” pitch. This is important because plastic coil construction is .250” pitch and this makes it faster and easier to drive the coils into the book.With fully dis-engagable punch pin design, 0.250” pitch is far superior to 0.248” pitch. It makes books stronger and tolerant of paper size fluctuation, which is very common in today’s digital printing (letter size sheets 8.5”x11” cut from 12” x 18” sheets). DFG only uses 0.248” pitch for low cost coil machines that don’t have dis-engagable punch pin design.

Manual Punch & Power Bind Operation: Heavy Duty Manual Coil Punching and Coil Binding with the simple press of a foot pedal.

Extended Single Punching Length: Punch any length of paper with our open throat die and alignment pin. DFG’s design makes it possible to punch paper of any length with no restrictions. Whatever your paper length is, you can punch it on the Coil Ultimate M. After the first punch, put one hole through the alignment pin to keep your subsequent punches aligned correctly and punch again. You will have perfect alignment for the full length of paper.

Super Strength Punch Mechanism: Cast-hardened & heat-treated precision steel punch pins provide superior strength & hardness. You add DFG’s lubrication system, and that drastically reduces friction and punch pin wear. This equates to longer machine life and a sharp clean perforation every time for the end user. High-Speed, commercial punches that cost over $30,000 lubricate their punch pins. DFG utilizes this technology in our commitment to taking the extra step to deliver the best machine possible to the market place.

Heavy duty Chassis: Countless years of experience has led DFG to produce a machine with the most sophisticated design, testing methods, and manufacturing techniques to develop the most rigid heavy duty chassis in its class at 29% less overall machine weight.

New Patent Pending SERVOGROVE ™ Roller Binding System: This new roller system binds small or larger books (up to 22 mm) effortlessly. Absolutely no costly separate coil inserter needed. Manually binds any size book. The SERVOGROVE ™ Roller Binding System dramatically increase binding speed, when compared against smooth roller systems by 50%. Once the coil is started, simply lay the book against the grooved roller. The coil is easily inserted into the book, making this inserter one of the easiest-to-use. Top-mounted roller position will give the operator greater control, improve their efficiency, and have less operator fatigue, which improves production. A foot-pedal activates the roller and is compatible with plastic & metal coils.

Full Die Disengagement Pins: Utilizing the DFG’s World’s First full disengagement-pin design for coil binding machines (recently copied by other manufacturers), our punched paper is free from partial punches, on any size project. Our disengagement-pin design uses independent coil spring mechanisms on each pull pin that allows the pins to disengage with a crisp snapping action. Our punch pins are heat treated and precisely ground to ensure consistent, clean, punching.

J-Shaped Book Pre-former Guide: It is essential when binding thicker books (1/4” or thicker) to have the ability to form the book to the proper radius of the Coil. This is why DFG has developed the J-Shaped Book Pre-former Guide as opposed to utilizing U shaped pre-former. The J-shaped Book Pre-former Guide supports the book better than a U shape guide because it supports the back of the book better. This solves book buckling and will assist the operator to properly shape the book’s spine, for faster & easier coil insertion. The J-shaped pre-former concept is widely used in larger, automatic binding machines.

Side Margin Control: Allows you to evenly center your punch pattern on your sheet.

Punching Margin Control: Provides the correct punch depth for each coil size. This will maximize the book's tear resistance

Rugged Die Cast Metal Construction: The Coil Ultimate M is made of DFG precision engineered die-casting base and side plates rather than low-cost, flexible sheet metal like some other machines in its class. DFG uses die casted metal for the base and sides of the housing unit to insure your machine is solid in all the important places which significantly improves machine life as compared to sheet metal base construction. Any base deflection can shorten the life of the machine

Large Waste Drawer

Non-Skid Feet

Includes DFG’s Oval Hole Coil Crimpers

Coil Ultimate M Specifications:

Model: |

Coil Ultimate M |

Punching Capacity |

1-25 sheets one punch (20#) (Most people punch up to 20 sheets) |

Binding Capacity |

Electrical binding up to 7/8”. Manual binding for any size |

Disengagement Pins |

Full |

Punch Length |

Any Length thanks to the fully disengagement pins and open throat design |

Hole Pattern |

True 4:1 pitch. 5 mm x 4 mm Double “D” hole |

Power Supplier |

110 V AC, 60 HZ |

Warranty |

One year limited |

Punches a double “D” oval hole (4x5mm hole) which increases the binding speed and makes it easier to bind thicker books. DFG double “D” oval hole is a True .250” pitch. This is important because plastic coil construction is .250” pitch and this makes it faster and easier to drive the coils into the book. With fully dis-engagable punch pin design, 0.250” pitch is far superior to 0.248” pitch. It makes books stronger and tolerant of paper size fluctuation, which is very common in today’s digital printing (letter size sheets 8.5”x11” cut from 12” x 18” sheets). DFG only uses 0.248” pitch for low cost coil machines that don’t have dis-engagable punch pin design. For any length and thickness book: Punch any length of paper with our open throat die and alignment pin. DFG’s design makes it possible to punch paper of any length with no restrictions. Whatever your paper length is, you can punch it on the BOB Coil E. After the first punch, put one hole through the alignment pin to keep your subsequent punches aligned correctly and punch again. You will have perfect alignment for the full length of paper. Super Strength Punch Mechanism: Cast-hardened & heat-treated precision steel punch pins provide superior strength & hardness. You add DFG’s lubrication system, and that drastically reduces friction and punch pin wear. This equates to longer machine life and a sharp clean perforation every time for the end user. High-Speed, commercial punches that cost over $30,000 lubricate their punch pins. DFG utilizes this technology in our commitment to taking the extra step to deliver the best machine possible to the market place. Heavy duty Chassis: Countless years of experience has led DFG to produce a machine with the most sophisticated design, testing methods, and manufacturing techniques to develop the most rigid heavy duty chassis in its class at 29% less overall machine weight. New Patent Pending SERVOGROVE ™ Roller Binding System: This new roller system binds small or larger books (up to 22 mm) effortlessly. Absolutely no costly separate coil inserter needed. Manually binds any size book. The SERVOGROVE ™ Roller Binding System dramatically increase binding speed, when compared against smooth roller systems by 50%. Once the coil is started, simply lay the book against the grooved roller. The coil is easily inserted into the book, making this inserter one of the easiest-to-use. Top-mounted roller position will give the operator greater control, improve their efficiency, and have less operator fatigue, which improves production. A foot-pedal activates the roller and is compatible with plastic & metal coils. Full Die Disengagement Pins: Utilizing the DFG’s World’s First full disengagement-pin design for coil binding machines (recently copied by other manufacturers), our punched paper is free from partial punches, on any size project. Our disengagement-pin design uses independent coil spring mechanisms on each pull pin that allows the pins to disengage with a crisp snapping action. Our punch pins are heat treated and precisely ground to ensure consistent, clean, punching. J-Shaped Book Pre-former Guide: It is essential when binding thicker books (1/4” or thicker) to have the ability to form the book to the proper radius of the Coil. This is why DFG has developed the J-Shaped Book Pre-former Guide as opposed to utilizing U shaped pre-former. The J-shaped Book Pre-former Guide supports the book better than a U shape guide because it supports the back of the book better. This solves book buckling and will assist the operator to properly shape the book’s spine, for faster & easier coil insertion. The J-shaped pre-former concept is widely used in larger, automatic binding machines. Side Margin Control: Allows you to evenly center your punch pattern on your sheet. : The BOB Coil M is made of DFG precision engineered die-casting base and side plates rather than low-cost, flexible sheet metal like some other machines in its class. DFG uses die casted metal for the base and sides of the housing unit to insure your machine is solid in all the important places which significantly improves machine life as compared to sheet metal base construction. Any base deflection can shorten the life of the machine Exclusive built-in lubrication system to ensure longer punching tool life.

|

||||||||||||||||||||

Punches a double “D” oval hole (4x5mm hole) which increases the binding speed and makes it easier to bind thicker books. DFG double “D” oval hole is a True .250” pitch. This is important because plastic coil construction is .250” pitch and this makes it faster and easier to drive the coils into the book. With fully dis-engagable punch pin design, 0.250” pitch is far superior to 0.248” pitch. It makes books stronger and tolerant of paper size fluctuation, which is very common in today’s digital printing (letter size sheets 8.5”x11” cut from 12” x 18” sheets). DFG only uses 0.248” pitch for low cost coil machines that don’t have dis-engagable punch pin design. Extended Single Punching Length: Punch any length of paper with our open throat die and alignment pin. DFG’s design makes it possible to punch paper of any length with no restrictions. Whatever your paper length is, you can punch it on the TitanCoil Eagle. After the first punch, put one hole through the alignment pin to keep your subsequent punches aligned correctly and punch again. You will have perfect alignment for the full length of paper. Super Strength Punch Mechanism: Cast-hardened & heat-treated precision steel punch pins provide superior strength & hardness. You add DFG’s lubrication system, and that drastically reduces friction and punch pin wear. This equates to longer machine life and a sharp clean perforation every time for the end user. High-Speed, commercial punches that cost over $30,000 lubricate their punch pins. DFG utilizes this technology in our commitment to taking the extra step to deliver the best machine possible to the market place. Heavy duty Chassis: Countless years of experience has led DFG to produce a machine with the most sophisticated design, testing methods, and manufacturing techniques to develop the most rigid heavy duty chassis in its class at 29% less overall machine weight. New Patent Pending SERVOGROVE ™ Roller Binding System: This new roller system binds small or larger books (up to 22 mm) effortlessly. Absolutely no costly separate coil inserter needed. Manually binds any size book. The SERVOGROVE ™ Roller Binding System dramaticaly increase binding speed, when compared against smooth roller systems by 50%. Once the coil is started, simply lay the book against the grooved roller. The coil is easily inserted into the book, making this inserter one of the easiest-to-use. Top-mounted roller position will give the operator greater control, improve their efficiency, and have less operator fatigue, which improves production. A foot-pedal activates the roller and is compatible with plastic & metal coils. Full Die Disengagement Pins: Utilizing the DFG’s World’s First full disengagement-pin design for coil binding machines (recently copied by other manufacturers), our punched paper is free from partial punches, on any size project. Our disengagement-pin design uses independent coil spring mechanisms on each pull pin that allows the pins to disengage with a crisp snapping action. Our punch pins are heat treated and precisely ground to ensure consistent, clean, punching. J-Shaped Book Pre-former Guide: It is essential when binding thicker books (1/4” or thicker) to have the ability to form the book to the proper radius of the Coil. This is why DFG has developed the J-Shaped Book Pre-former Guide as opposed to utilizing U shaped pre-former. The J-shaped Book Pre-former Guide supports the book better than a U shape guide because it supports the back of the book better. This solves book buckling and will assist the operator to properly shape the book’s spine, for faster & easier coil insertion. The J-shaped pre-former concept is widely used in larger, automatic binding machines. Side Margin Control: Allows you to evenly center your punch pattern on your sheet. Punching Margin Control: Provides the correct punch depth for each coil size. This will maximize the book's tear resistance Rugged Die Cast Metal Construction: The TitanCoil Eagle is made of DFG precision engineered die-casting base and side plates rather than low-cost, flexible sheet metal like some other machines in its class. DFG uses die casted metal for the base and sides of the housing unit to insure your machine is solid in all the important places which significantly improves machine life as compared to sheet metal base construction. Any base deflection can shorten the life of the machine Large Waste Drawer Non-Skid Feet Includes DFG’s Oval Hole Coil Crimpers

TitanCoil Eagle Specifications:

|

||||||||||||||||||||

Low cost version of the TitanCoil Eagle for the people who want a heavy duty, manual punch and power coil binding, but have a limited budget. For specs and video, please see TitanCoil Eagle.

|

||||||||||||||||||||

TitanCoil Oval is ideal for mid to high volume coil book binding. This oval hole punching machine is built upon DFG's industry leading Titan Coil series machines. After one and half years of intensive research and development, this fully featured, new and improved DFG TitanCoil Oval machine, raises the bar for coil binding. Rugged Die Cast Metal Construction: Made of sturdy die-casted metal rather than flexible sheet metal, the TitanCoil Oval is a heavy duty, reliable, user-friendly, and functional machine. DFG uses die casted metal for the base and sides of the housing unit to insure your machine is solid in all the important places which significantly improves machine life as compared to sheet metal base construction. Punches a double “D” oval hole (4x5mm hole) which increases the binding speed and makes it easier to bind thicker books. DFG double “D” oval hole is a True .250” pitch. This is important because plastic coil construction is .250” pitch and this makes it faster and easier to drive the coils into the book.With fully dis-engagable punch pin design, 0.250” pitch is far superior to 0.248” pitch. It makes books stronger and tolerant of paper size fluctuation, which is very common in today’s digital printing (letter size sheets 8.5”x11” cut from 12” x 18” sheets). DFG only uses 0.248” pitch for low cost coil machines that don’t have dis-engagable punch pin design. Double “D” Oval Holes: Virtually zero tolerance Double “D” oval hole (4 x 5 mm) further improves the binding and book quality, compared to typical oval hole and round hole. With built-in DFG’s patent pending SERVOGROOVE ™ roller binding system, the TitanCoil Oval machine significantly saves binding time by 50%, compared to smooth roller design. Absolutely no expensive separate coil inserter needed! Fully Dis-engagable pins: ensures a completely clean professional punch without partial punches on any length of paper. Our new design further improves the life of the punching tool since our old design has been copied by other manufacturers. .250” pitch design, for certain size coils, coil will automatically stop after going through the end of the book. .250” pitch design prevents over-shoot. Most binding machines in the current market insert slow and they do not consider over-shoot. DFG engineers developed 0.248” pitch 4 x 5 mm oval hole in 1996 while they were working for another company. The reason for choosing 0.248” is some automatic punches did not have dis-engagable punch pins at that time. In 1996, there was no table top oval hole punch and binding machines. Countless years of experience has led DFG to produce a machine with the most sophisticated design, testing methods, and manufacturing techniques to develop the most rigid heavy duty chassis in its class at significantly less overall machine weight. TitanCoil Oval Benefits:

TitanCoil Oval Specifications:

|

||||||||||||||||||||

Coming soon...

|

||||||||||||||||||||

OfficeECoil –manual punching and power coil binder OfficeECoil is ideal for small volume coil book binding. Double “E” Oval Holes Virtually zero tolerance Double “D” oval hole (6 x"5 mm) further improves the binding and book quality, compared to typical oval hole and round hole. OfficeECoil significantly saves binding time by 50%, compared to smooth roller design. Most office environments uses 11” sheets. OfficeECoil (0248” oval hole pitch) is a good fit for this application. If a different sheet size needs to be punched, we recommend upgrading to a machine that has 0.250” pitch oval hole. Side Margin Control: Center punched holes quickly and easily Adjustable Punch Margin: Assists in controlling the punch margin depth in order to maximize a book’s tear resistance Non-Skid Feet: Firmly holds machine to work surface

OfficeECoil Specifications:

|

DFG’S BOB Coil M is an extra heavy duty manual coil punch and power binding machine. It can punch up to 25 sheets (20#, double D oval hole) or 3 mm hardboard in one punch, if you have a strong arm. With DFG’s SERVOGROVE™ Roller Binding System, it binds small or larger books (up to 22 mm) effortlessly. Lager size coil is not difficult with some practice. BOB Coil M can punch and bind any length and thickness of book.

DFG’S BOB Coil M is an extra heavy duty manual coil punch and power binding machine. It can punch up to 25 sheets (20#, double D oval hole) or 3 mm hardboard in one punch, if you have a strong arm. With DFG’s SERVOGROVE™ Roller Binding System, it binds small or larger books (up to 22 mm) effortlessly. Lager size coil is not difficult with some practice. BOB Coil M can punch and bind any length and thickness of book.  TitanCoil Oval - heavy-duty manual punching and electric coil binding machine.

TitanCoil Oval - heavy-duty manual punching and electric coil binding machine.